Rail grinders are widely used as a tool for maintaining and restoring the profile of railway tracks throughout the UK, North America and Europe and have been in use since the turn of the 20th Century. The petrol powered engine of the rail grinder is designed to remove any irregularities if the rail track is worn which in-turn helps to extend its lift and improve the ride of trains using the track.

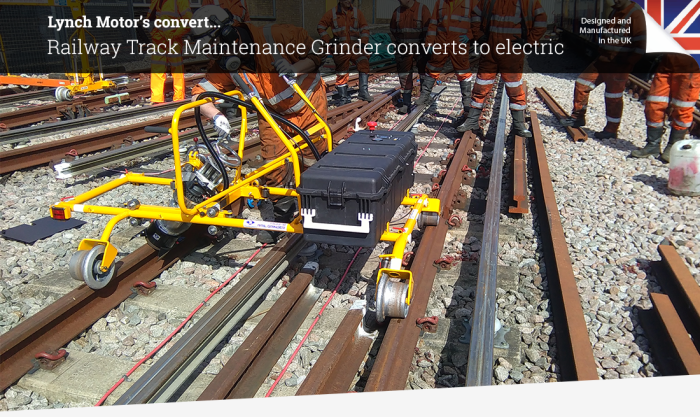

'The recently converted, electric Railway Grinder in use for the very first time'

'The pelicase (box) which encases the controller, battery and all the electronics required to power the rail grinder'

In this example, Lynch Motors converted a petrol powered engine to electric. Pictured is the pelicase (box) which encases the controller and battery alongside all of the electronics required to power the rail grinder via electrics as opposed to petrol.

Initially the rail grinder units were powered using traditional AGM batteries and although the results were positive and proved successful, the unit was let down by its weight. More recently, to combat this, the power assembly system has been upgraded with LiPo4 battery technology which has not only more than doubled the running time, but also reduced the weight of the rail unit substantially. Moreover, the new electric powered units have inbuilt safety features to protect the Lynch Motor, batteries and most importantly the user, making rail grinding simple, greener and more environmentally friendly.

Lynch Motors look forward to developing new applications for the rail industry, utilising the skills and knowledge of our team, all of which is based around the unique DC Motor.

If you are interested in finding out how Lynch Motors can help with your railway project please get in touch on 01404 597476 and we will be more than happy to advise you on the best solution for your project.